Tailings Management

The management of tailings and the structural integrity of our tailings storage facilities are critical to community safety and environmental protection.

Our tailings storage facilities (TSFs) are engineered structures designed and constructed to hold mineral waste (tailings) from our processing facilities. We design, construct and manage TSFs in compliance with all host country regulations and, where applicable, any additional requirements consistent with our management standards and framework.

Our TSF Management Statement of Position commits our company to the safe management of TSFs throughout the tailing’s facility life cycle (including closure) by avoiding and mitigating potential harm to the environment, employees and affected peoples and communities. It was updated in 2021 to align with the requirements of the Global Industry Standard on Tailings Management.

The types of TSFs we have

At OceanaGold we utilise four methods of tailings storage:

- Downstream construction;

- Downstream construction with upstream lift;

- In-pit storage and capping; and

- Paste backfill underground.

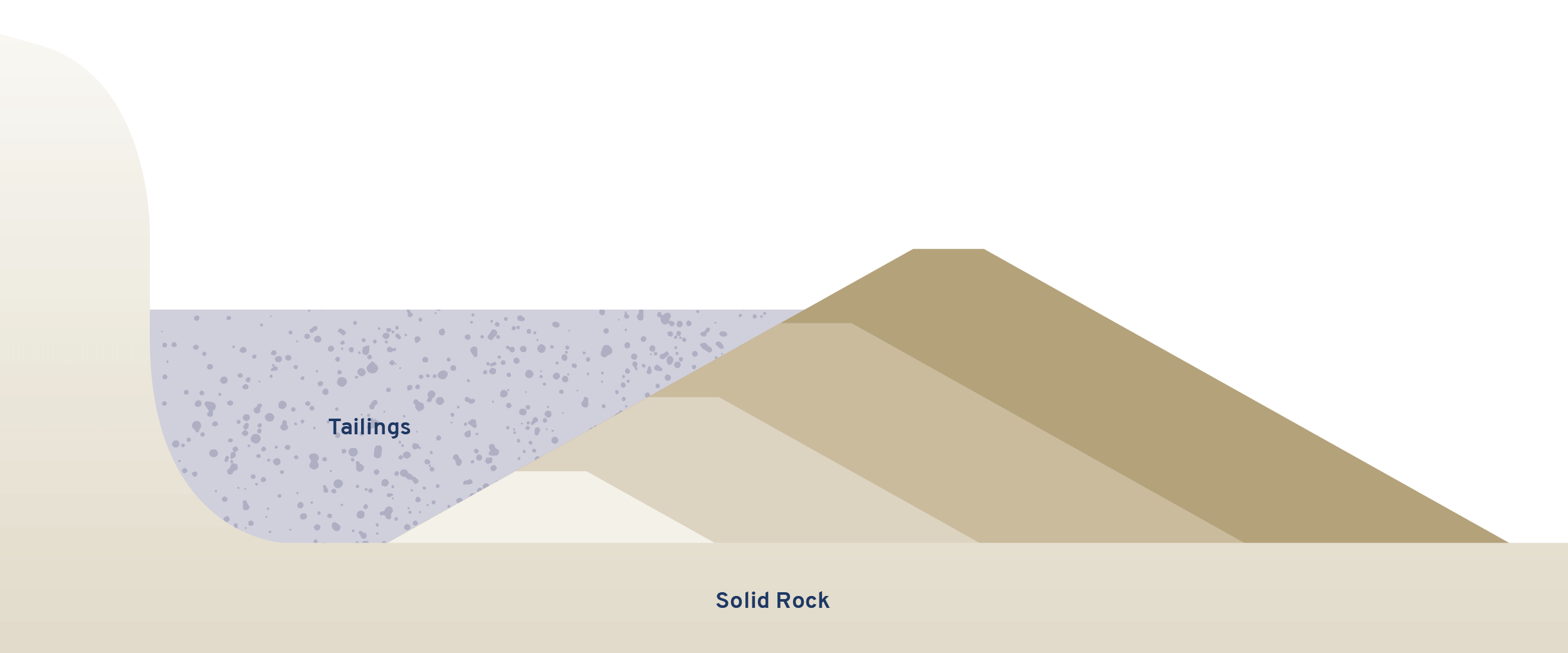

Downstream construction

Downstream TSFs are constructed with a single embankment (wall) formed with waste rock to create engineered embankments that are progressively raised to provide additional space for tailings storage. We utilise the downstream method at the Waihi Gold Mine, Macraes Operations, Haile Gold Mine, the Didipio Mine and Junctions Reef.

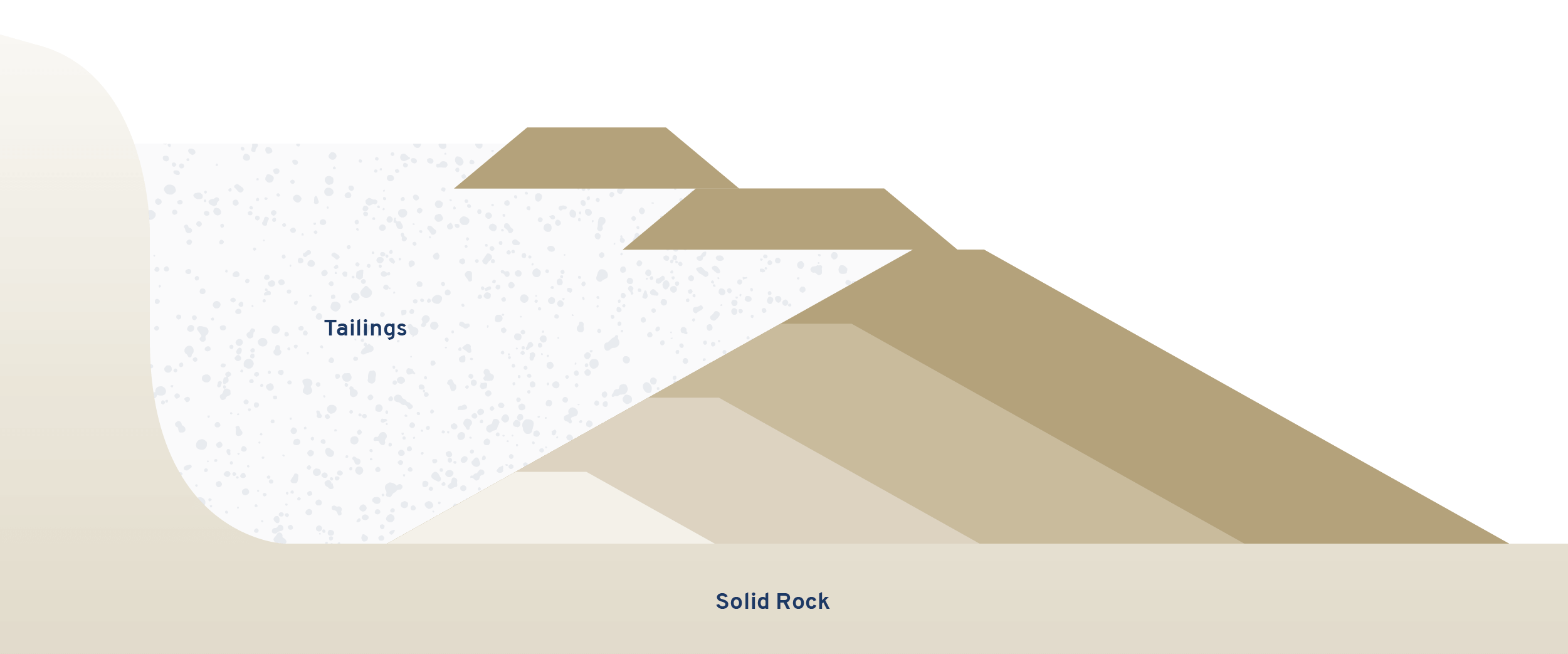

Downstream construction with upstream lift

The foundation of the facility embankment is the downstream construction method. Tailings are then discharged into the dam and harden to form the foundation for the next level of wall. This method was utilised at two of the now-closed TSFs at the Macraes Operations.

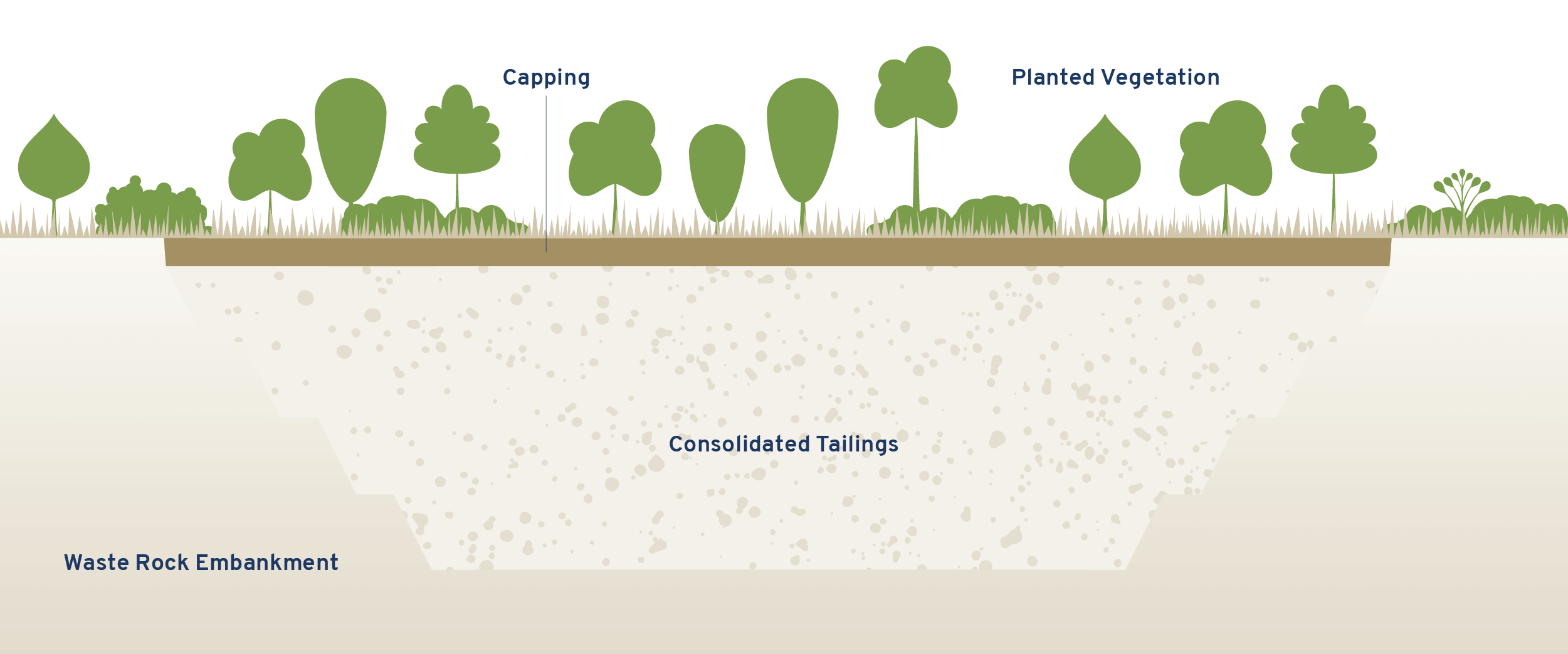

In-pit storage and capping

Once an open pit is no longer being used it can be backfilled with tailings, as long as potential seepage and other factors can be managed. Once the pit is filled it is then capped with layers of rock and soil, which can be planted. We used the in-pit storage and capping method at the now-closed Souvenir open pit at the Globe Progress Mine at Reefton and at Junctions Reef.

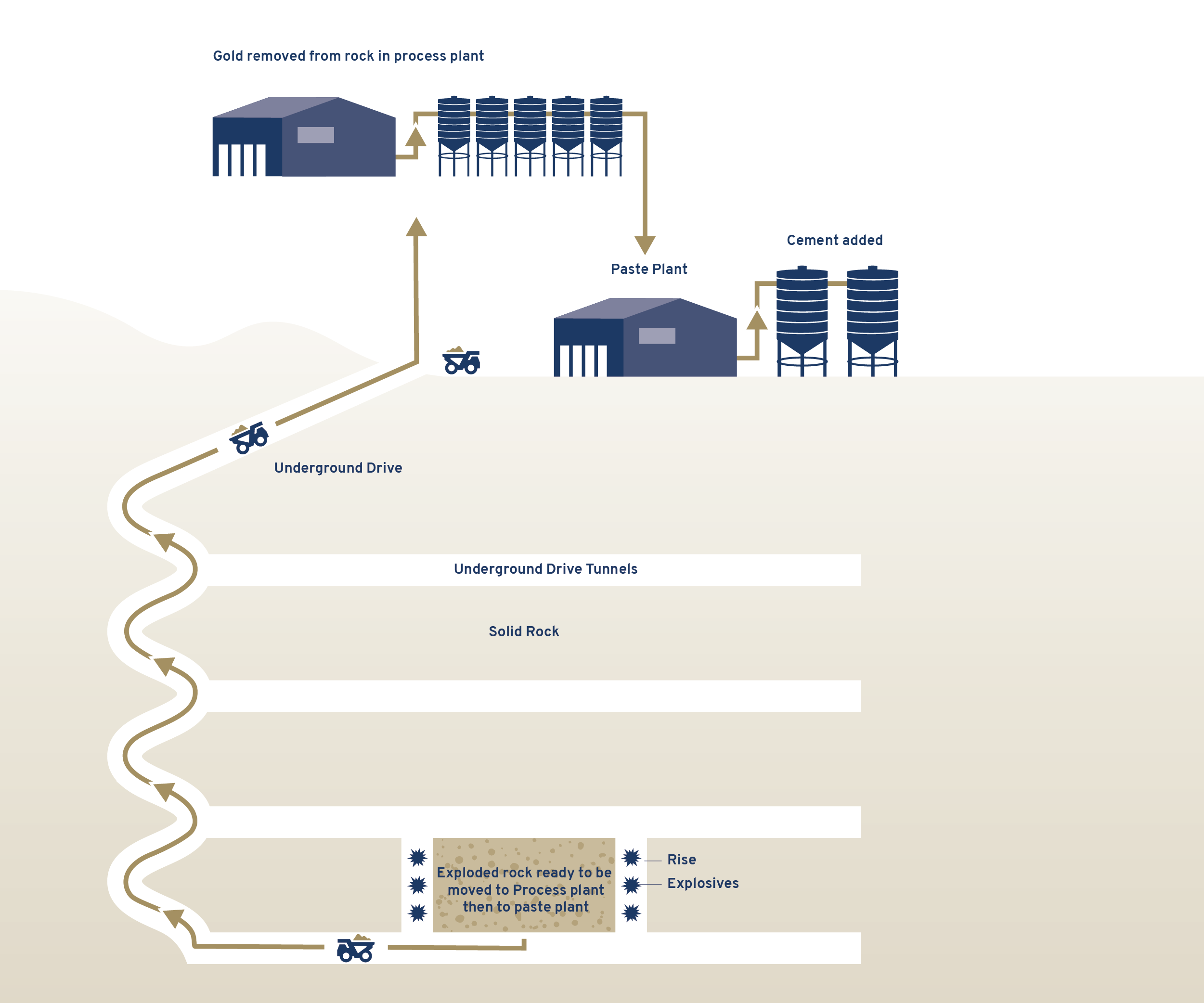

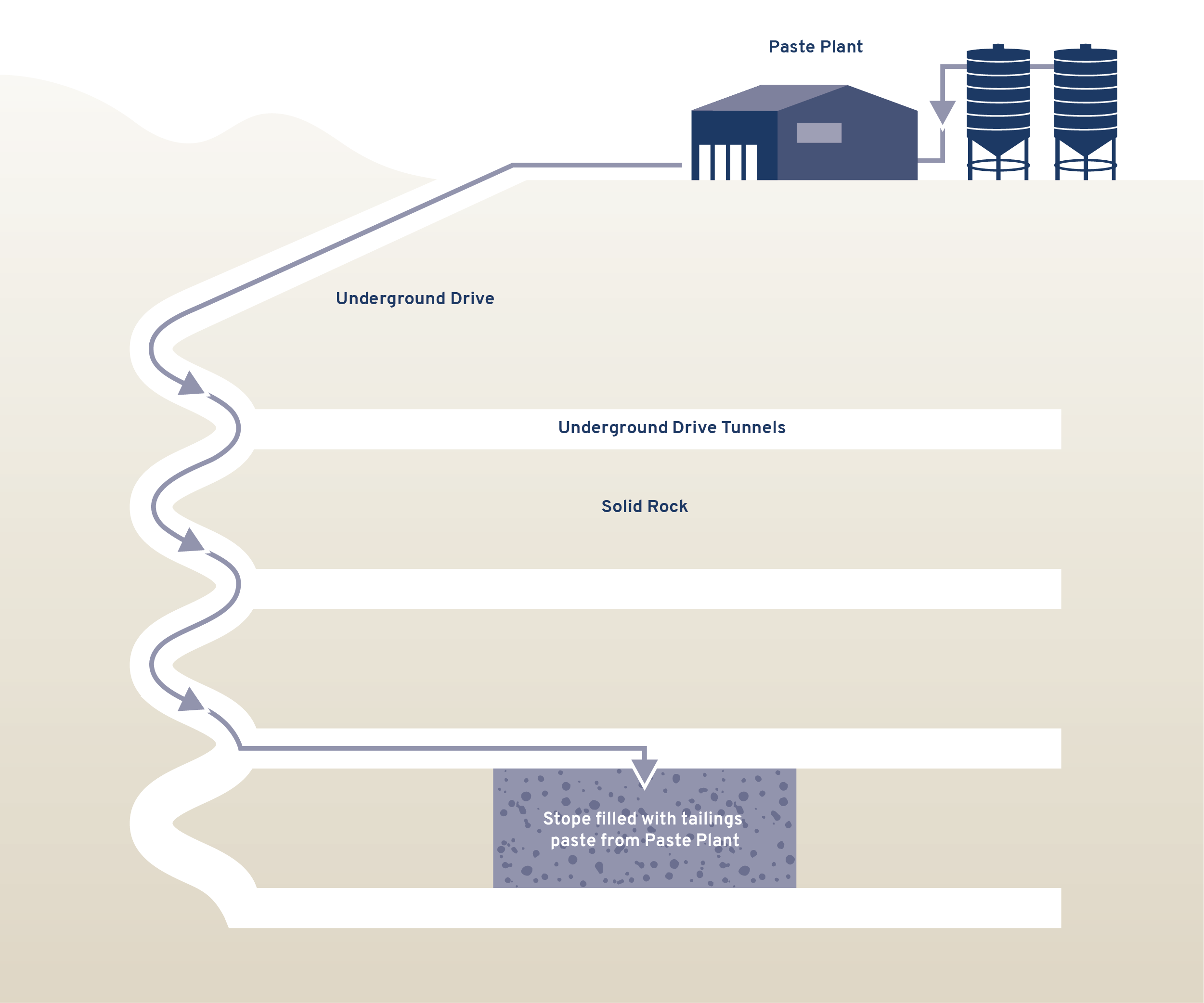

Paste backfill

Once processing is complete up to 40% of the mine tailings can be diverted to a paste plant where it is mixed with cement and used as backfill material for underground mine voids, which reduces the volume of tailings delivered to the TSF. We utilise the paste backfill method at our Didipio Mine.

TSFs at our current operations

Didipio Mine, Philippines

Didipio has one TSF, which was designed to exceed compliance standards as stipulated in the guideline issued by the Philippine Department of Environment and Natural Resources and the Australian National Committee on Large Dams’ Guidelines on Tailings Dams.

Quality control and assurance of construction criteria and materials is undertaken by an independent engineering specialist with support from operational personnel.

Quarterly and annual monitoring has been implemented since construction commenced by an independent third-party technical expert. In addition, an external review was conducted by a separate independent third-party technical expert in October 2017.

Haile Gold Mine, United States of America

The TSF at Haile became operational in 2016 following final regulatory approval by the South Carolina Department of Health and Environmental Control (SC-DHEC), which holds jurisdictional authority over the facility through their Dam Safety Division.

We commissioned an independent technical expert to undertake a Final Construction Inspection Report and a Dam Safety and Structural Review Inspection Report. In addition, the SC-DHEC undertook technical reviews prior to granting approval to operate the TSF.

Waihi Operation, New Zealand

Waihi has two TSFs, although only one is operation. Tailings deposits into the closed and rehabilitated facility ceased in 2005.

Both TSFs were designed by an independent third-party technical expert in accordance with the New Zealand Society of Large Dams. Both TSFs have monitoring plans that are reviewed and approved by the local regulators and undergo extensive internal monitoring. They also have detailed annual regulatory reporting requirements in relation to the stability and performance of pollution controls and environmental effects.

Annual reviews of the construction and operation of the TSFs are undertaken by an independent project engineer. An expert peer review panel has also been appointed to review the annual monitoring program and completion of the facility. This panel comprises independent third-party technical experts appointed by the local regulatory bodies, with expertise in geotechnical engineering, geochemistry, groundwater and rehabilitation.

These annual reviews, conducted since 1987, encompass the following:

- Design, construction, monitoring, performance and stability reports from embankment construction;

- Operation, maintenance, and surveillance records for the period of review; and

- Other internal and external reports related to operations and closure of TSFs, including reviews of compliance against the New Zealand Society of Large Dams (NZSOLD) New Zealand Dam Safety Guidelines.

Macraes Operation, New Zealand

Macraes has three TSFs – two are now closed and will be rehabilitated and one remains operational. All undergo extensive internal monitoring and have detailed annual regulatory reporting requirements regarding the stability and performance of pollution controls and environmental effects.

In 2016 the Macraes TSFs were reviewed by an independent third-party technical expert, concluding in 2017. The review updated a similar assessment performed in 2011, and included design, operation and monitoring processes and a risk assessment of the safety and stability of the tailings embankments based on their status. It also reviewed compliance against the New Zealand Society of Large Dams’ New Zealand Dam Safety Guidelines.